General

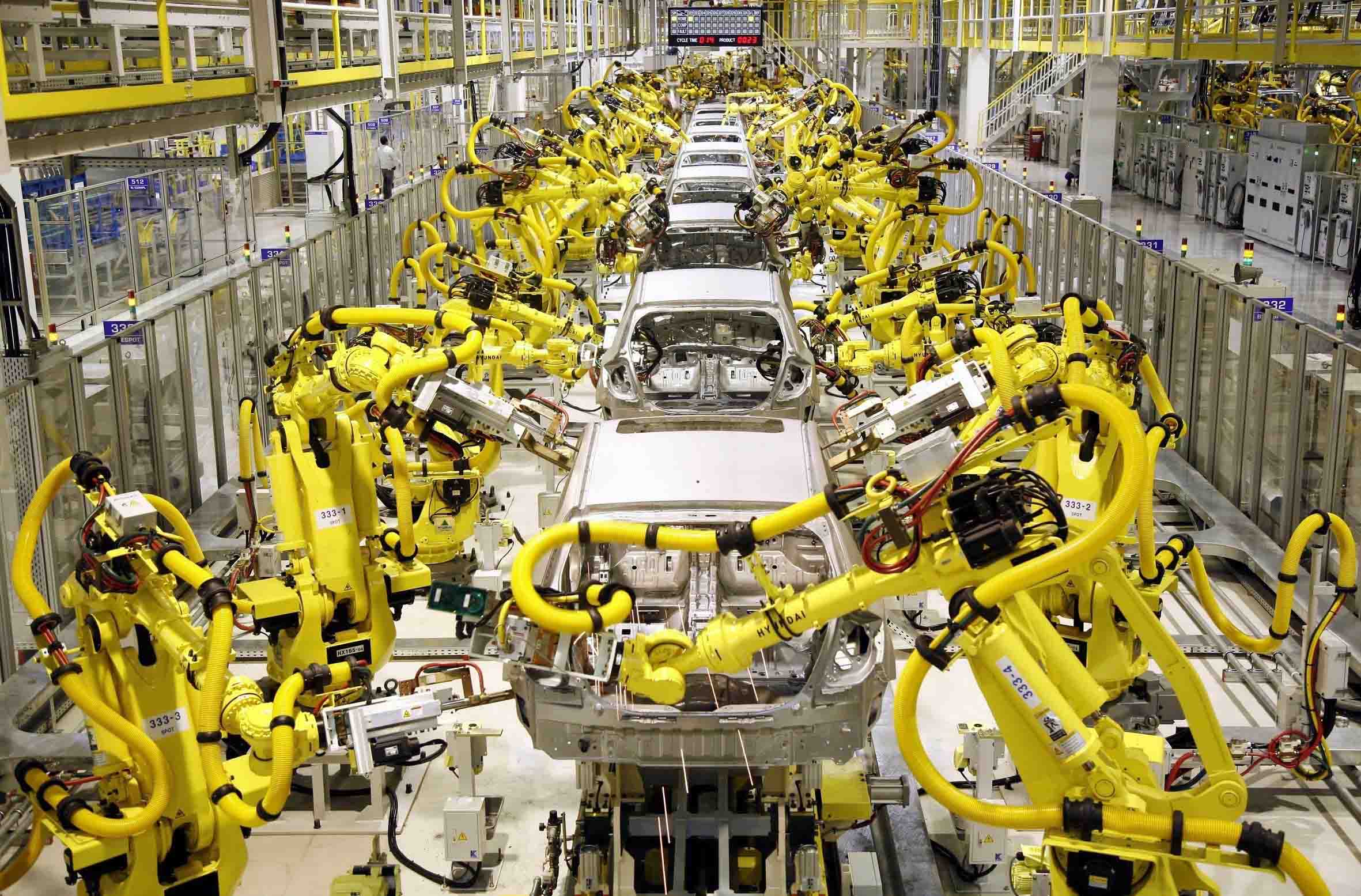

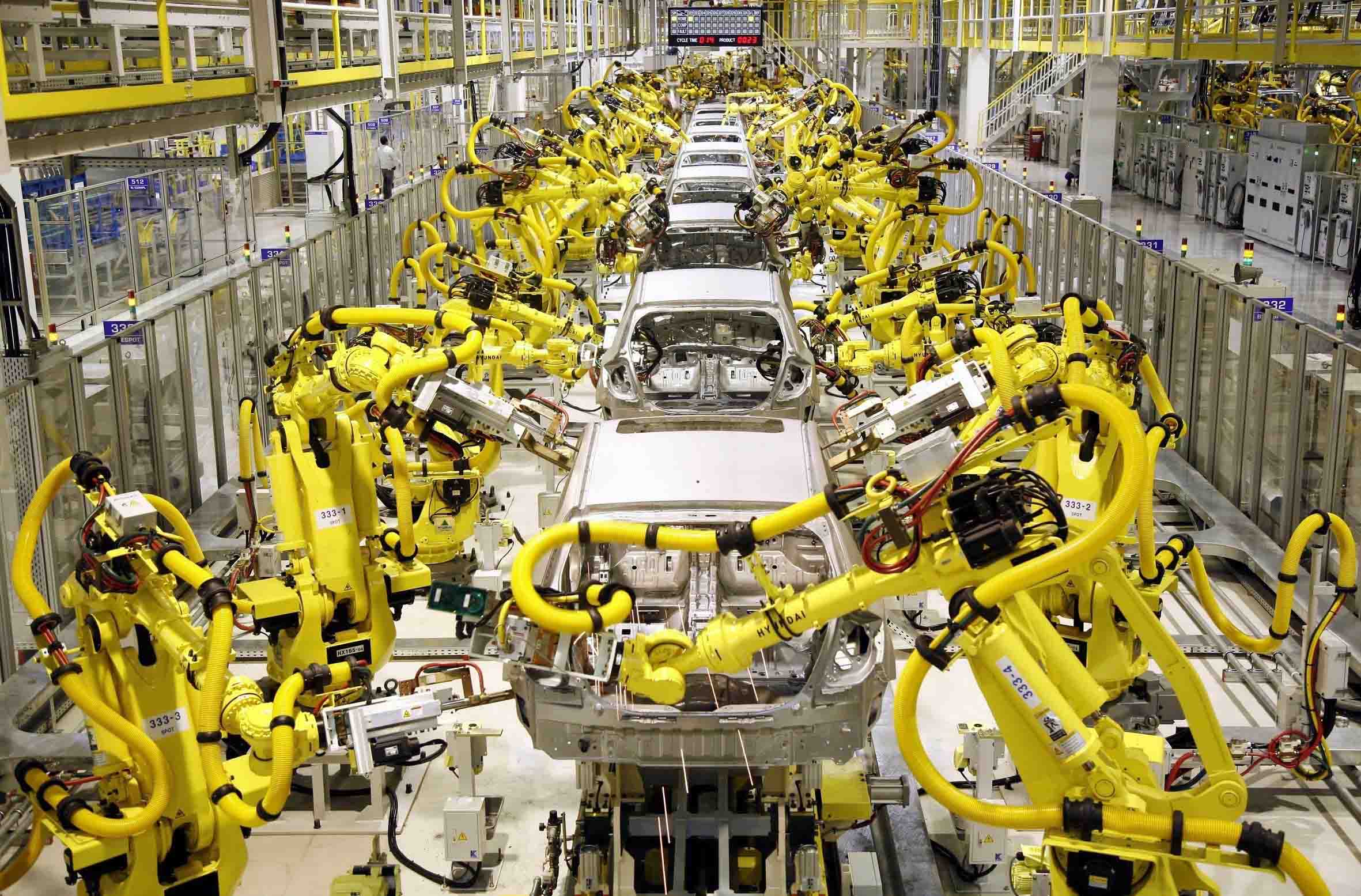

Researchers have Found that Factory Robots can Easily be Hacked

As the world’s industrial facilities move to mechanization, a progression of tests discovers some disturbing defects.

By 2018, there could be 1.3 million robots in manufacturing plants all around. That is 1.3 million machines in danger of being hacked.

Robotization is rapidly assuming control over the economy, anticipated that would slaughter off 6 percent of all US employments by 2021. Plants that make your telephones, autos and planes as of now depend essentially on machines to naturally assemble gadgets.

People can’t stay aware of a robot’s pace, quality and solidness, however, in any event they have machines beat on cybersecurity.

A progression of tests directed by Politecnico Di Milano and cybrsecurity firm Trend Micro found that processing plant robots has powerless system security. A few frameworks utilized straightforward usernames and passwords that couldn’t be changed, while others didn’t require a secret word. The firm has taken a gander at robots from ABB, Fanuc, Mitsubishi, Kawasaki and Yaskawa.

The modern machines likewise have poor programming assurance, and some keep running on obsolete programming, as per the association’s examination paper. The group discovered countless robots utilizing IP addresses that are open, which expands the danger of programmers getting simple get to.

Administrators and software engineers can deal with their machines remotely, sending charges to robots through their PCs or telephones. In the event that the association is uncertain, programmers could commandeer the machines, prompting harm and item surrenders.

The scientists tried a robot from ABB, which was customized to draw a straight line. By figuring out the RobotWare control program and the RobotStudio programming, the analysts hacked the machine’s system and changed it to draw a line that 2 millimeters off.

Machines are modified to be to a great degree exact in their developments, in light of the fact that the smallest error can bring about disastrous imperfections.

ABB has since settled the defects in its machine’s product, however Trend Micro’s discoveries raise concerns all the more for the most part for mechanization later on. The firm suggests organizations set up mechanical robot cybersecurity benchmarks before mechanization assumes control over each industrial facility.

Technology4 weeks ago

Technology4 weeks ago10 Best Generative AI Tools to Scale Your Business in 2024

Games2 weeks ago

Games2 weeks agoA Brief History of Solitaire: From Cards to Computers

Model3 weeks ago

Model3 weeks agoKatelyn Ernst: Bio, Age, Lifestyle, Career, Hair & Eye Color, Net Worth

Technology2 weeks ago

Technology2 weeks agoHow To Enhance Your Learning With Duolingo Podcasts?

Technology5 days ago

Technology5 days agoThe Website Design Workshop: Crafting User-Centric Sites

You must be logged in to post a comment Login